The Fragile Public Perception of Offshore Wind Energy

Offshore wind energy faces significant public relations challenges daily. Media coverage frequently highlights concerns about marine wildlife impacts, particularly whales. Local opposition (NIMBY – Not In My Back Yard) continues to grow in coastal communities. Many worry about disruption to generations-old fishing and maritime industries.

Consider the potential fallout from a high-profile accident during turbine installation at a major offshore facility. How would such an incident affect the already tenuous public perception? The OmniCrane™ technology directly addresses this vulnerability by minimizing the need for technicians to work at dangerous heights on turbine tops during WTG integration and maintenance.

Advanced Crane Technology: The Unsung Hero of Offshore Wind Success

Wind turbines may capture the spotlight in renewable energy, but supporting technologies like the OmniCrane™ are critical to delivering on climate commitments. This revolutionary lifting system is transforming what a crane means to offshore wind facilities, workers, and their families.

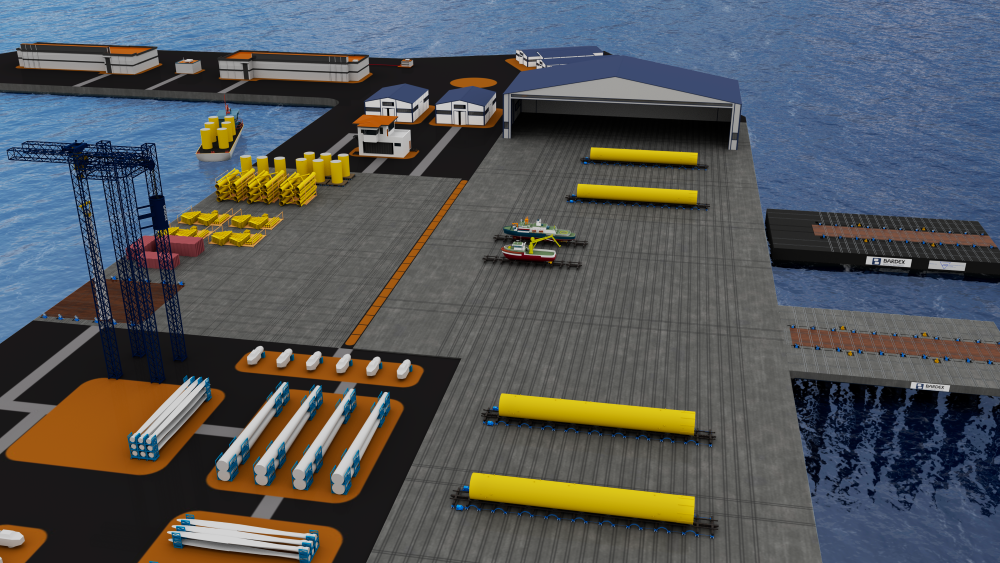

The Bardex OmniCrane™ provides a complete solution for lifting and positioning all wind turbine generator components, including tower sections, nacelle, hub, and blades. Its innovative approach allows for assembling the nacelle, hub, and two blades on land at quay level, significantly reducing:

- Number of heavy lifts required

- Dangerous over-water operations

- Safety risks to personnel

- Assembly complications

- Weather-related delays

Sustainable Financial Model for Local Economic Growth

Unlike traditional equipment manufacturers that rent cranes to ports, the OmniCrane™ operates on a unique ownership model where ports themselves own the equipment. This creates multiple advantages:

- Ports receive day rates from developers during installation and maintenance

- Equipment remains available for multiple industries when not used for wind projects

- Creates consistent revenue streams for local economies

- Supports stable, long-term local employment

- Keeps investment dollars circulating within regional economies instead of flowing to international rental companies

- The OmniCrane can be disassembled, transported, and/or sold, making it easier to finance.

The OmniCrane™ transforms heavy lifting from a logistical challenge into a strategic advantage for offshore wind development.

Solving Critical Challenges in Offshore Wind Installation

Floating offshore wind platforms present unique integration challenges that create significant bottlenecks. Traditional methods require floating platforms to remain quayside during tower and turbine integration, creating numerous operational risks. These conventional approaches limit integration activities to periods of extremely mild weather, as even minor wave action or wind becomes dramatically magnified at heights of 130+ meters above quay level.

Traditional Installation Methods: Key Risk Factors

Traditional offshore wind installation methods present numerous challenges:

- Worker Safety Risks: Over-water operations create significant safety hazards

- Weather Vulnerability: Tidal and wave activity cause platform oscillation, allowing work only during calmest conditions

- Complex Assembly Requirements: Aligning components at 130+ meter heights while suspended from boom cranes is dangerous and difficult

- Environmental Impact: Conventional diesel-powered cranes and required tug assistance generate substantial greenhouse gas emissions

- Operational Bottlenecks: Limited quayside space and pre-commissioning issues create production delays

- Ongoing Maintenance Challenges: Equipment availability for lifecycle maintenance presents logistical and financial uncertainties

For gigawatt-scale throughput, these issues must be addressed to reduce Levelized Cost of Energy (LCoE), accelerate installation timelines, and minimize the carbon footprint of floating offshore wind platforms.

The OmniCrane™ Solution: Revolutionizing Offshore Wind Installation

The Bardex OmniCrane™ system transforms offshore wind installation through innovative engineering. When combined with the OmniLift™, it provides a stable platform for turbine integration while eliminating over-water work requirements.

Key Advantages of the OmniCrane™ System:

- Ground-Level Assembly: Enables safer, more efficient assembly of sub-components at grade level

- Parallel Construction: Sub-assemblies can be built simultaneously with platform assembly and pre-staged

- Reduced Lift Requirements: Two blades can be installed into the hub before lifting, minimizing dangerous high-altitude operations

- Lower Environmental Impact: Grid-powered operation significantly reduces greenhouse gas emissions and carbon footprint

- Improved Schedule Reliability: Enables pre-commissioning of turbines on land with purpose-built design

- Future-Proof Investment: Adaptable to accommodate larger turbines (from 15MW to 22MW+) through modular design

- Multi-Industry Applications: Supports various maritime industries including Oil and Gas Decommissioning, Module Offloading, and Marine Construction

Engineering Excellence and Safety Standards

Safety isn’t merely integrated into the OmniCrane™ design—it’s foundational to its manufacturing process. Bardex manufacturing facilities maintain rigorous certifications:

- ISO 9001 Quality Management System

- ISO 14001 Environmental Management System

- ISO 45001 Occupational Health & Safety Management System

Merging Proven Technology with New Applications

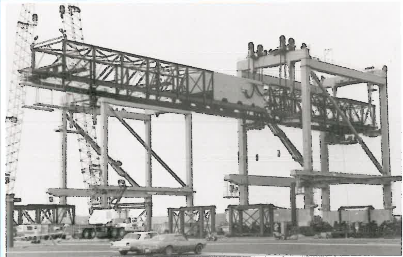

The OmniCrane™ builds upon Bardex’s decades of experience with chain jack lifting devices used in shiplifts and offshore oil floating production facility mooring systems. While leveraging proven technology, this application represents a significant advancement for the renewable energy sector.

The system features:

- Four lattice beam legs with modular bridging elements

- Horizontal skidding capability along quay-embedded beams

- 1500+ tonne capacity chain jack mounted on traversing beams

- Vertical lift capabilities with chain locker storage system and counterweight

- Slewing ability as an optional feature

- All components and features of the OmniCrane are field proven

An early Bardex® Chain Jack Crane used at the Port of Long Beach, California.

Every day is a good day when you’re designing the world’s biggest chain jacks.

Collaborative Innovation: Raising Industry Standards

Bardex aims to raise more than WTG components off the ground — we’re lifting industry expectations through collaboration.

Rather than focusing on pure R&D, we prioritize solutions that translate swiftly into real-world advancements. Our Sales team listens; our Engineering team answers. Every Bardex innovation over the last six decades has developed from the pain points our clients brought to us.

The OmniCrane’s inception has been no different. Its development has been a masterclass in cross- departmental and cross-organizational communication. And it won’t stop with just Sales, Engineering, and Client collaboration — when it’s time to manufacture, our Quality, Purchasing, Production teams will be vital to translating the paper design to reality. Raising the Bar isn’t good enough — Bardex Raises the Bar Together.