Patents

Making Things Better, Faster, Safer for Six Decades

Since the 1960s, we have pushed the boundaries of what is possible in efficiency, safety, and reliability. Our pioneering vision has led to game-changing solutions for positioning, restraining, and lifting heavy loads for the shipyard and oil and gas industries. And we bring that same commitment and talent to innovations for the burgeoning offshore wind industry.

To date, Bardex® has been awarded more than 20 U.S. and international patents. Visit our History page to take a deeper dive into our achievements.

Bardex Patents

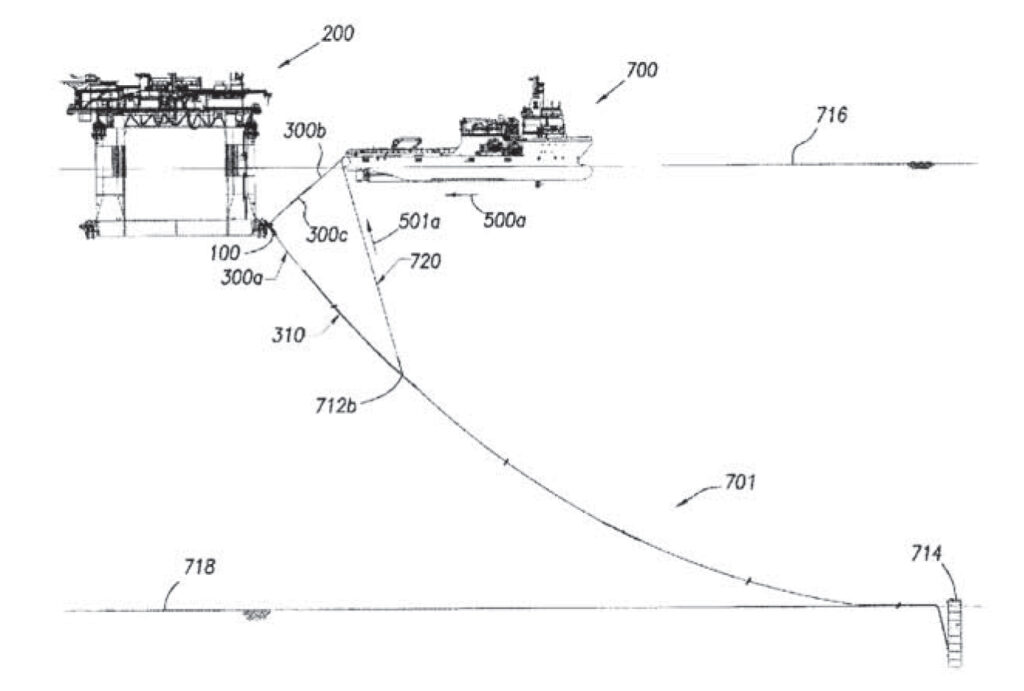

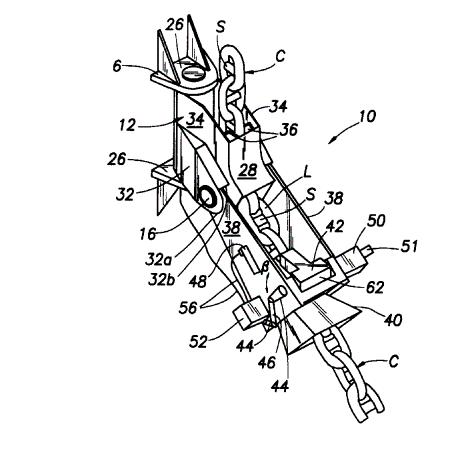

A method of mooring a floating vessel having a fairlead stopper coupled thereto is provided. The method includes retrieving a line pre-reeved on the fairlead stopper, connecting the line to an upper end of a mooring line, retrieving a second end of the line, connecting the second end to a winch of the AHV, and hauling in the mooring line to apply tension thereto.

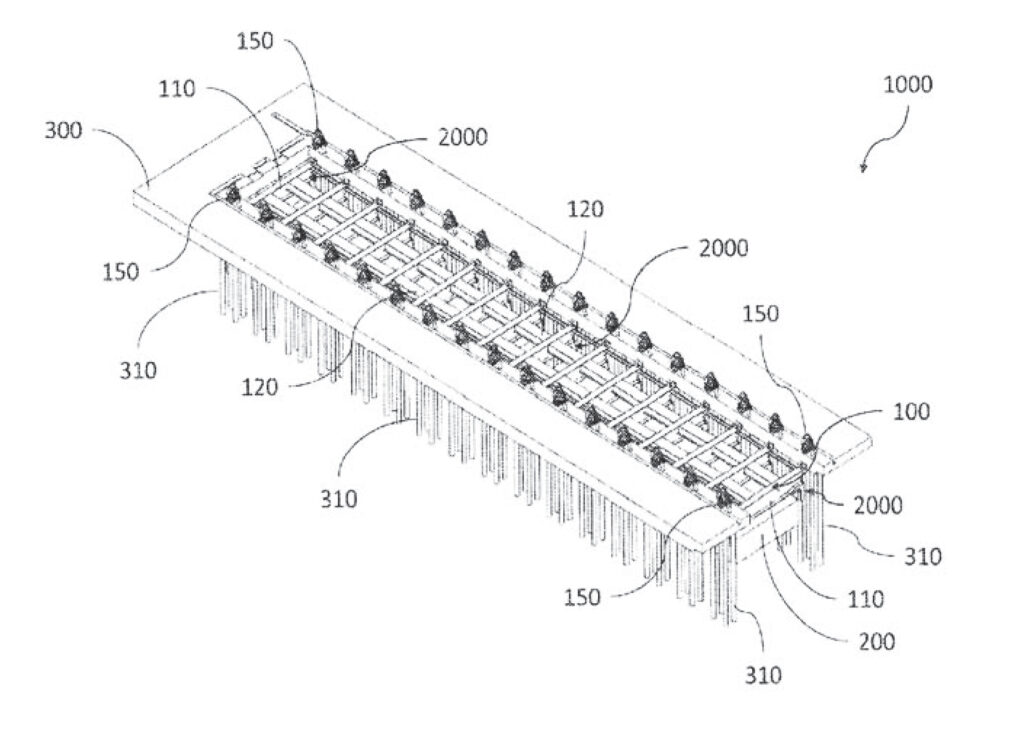

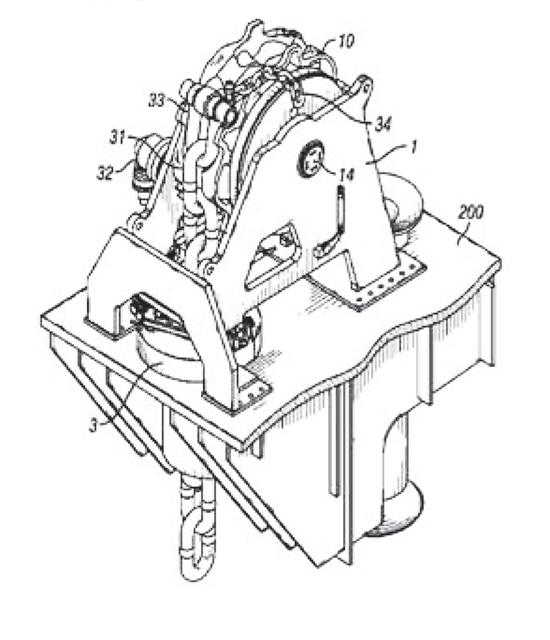

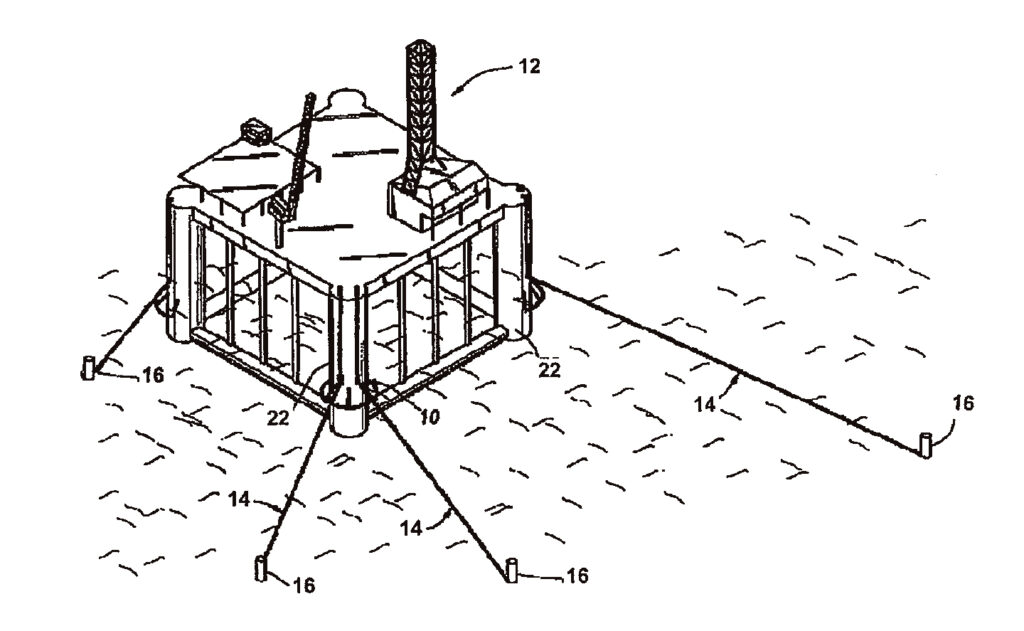

A shiplift includes a pier defining a space. The pier includes lifting apparatus. The shiplift includes a shiplift platform configured to fit with the space defined by the pier. One or more movable connectors are mechanically coupled to the shiplift platform. Each movable connector is configured to move into at least two positions.

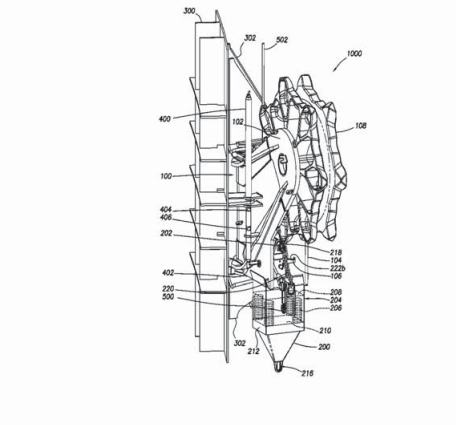

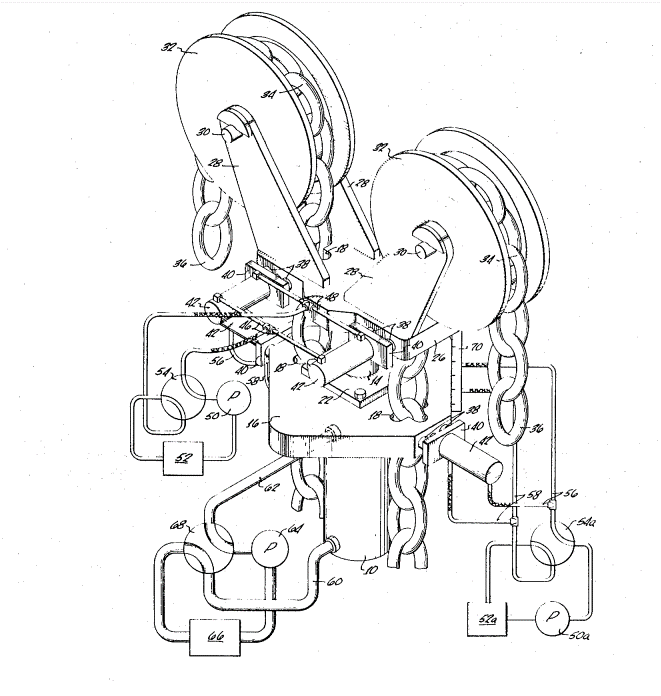

A chain mooring windlass may include a frame, a wheel, and an axel extending through the wheel and notably coupled to the frame. Drive assemblies may be coupled to the axel via a first-stage gear reduction including reduction gears.

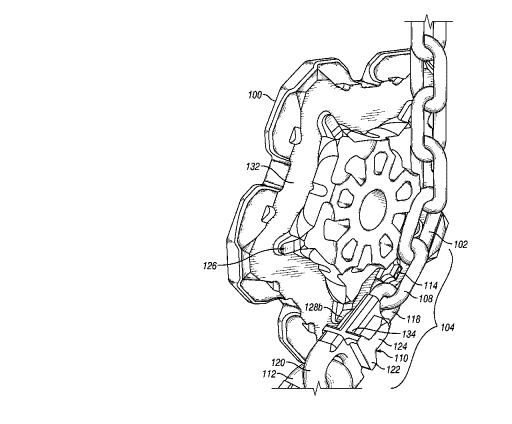

A connecting link assembly for connecting two chain sizes together. The connecting link assembly includes a smaller connecting link assembly sized according to the smaller chain size, a larger connecting link assembly sized according to the larger chain size, and a connecting component.

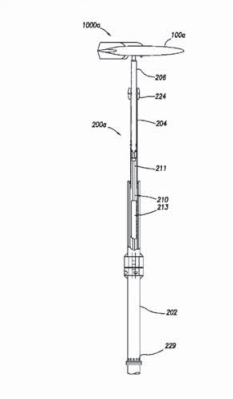

A self-aligning fairlead latch device is provided for guiding and securing an anchor chain between an offshore structure and an anchor. The fairlead latch device includes a latch housing pivotally mounted to a fairlead housing.

A turret-moored vessel with an improved bearing, turning, and locking system includes a floating hull, a turret supported by the hull and rotatable relative to the hull, and bearing assemblies forming an interface between the hull and turret.

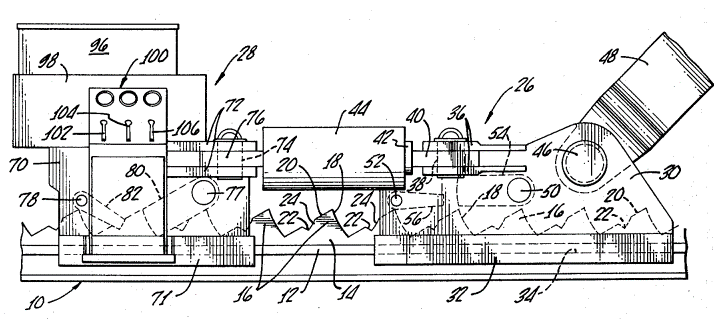

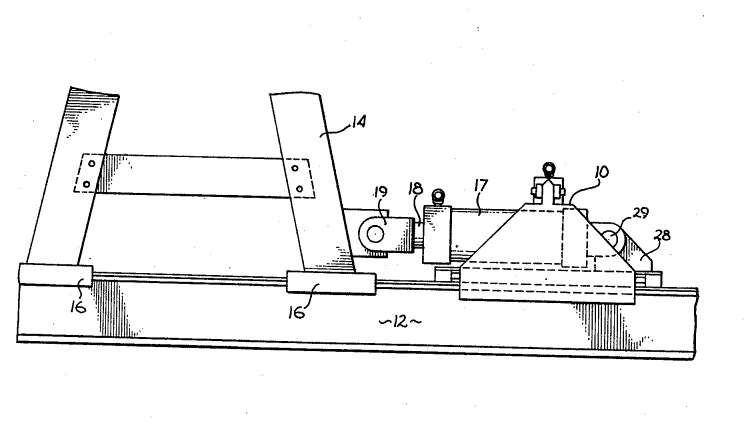

A jacking apparatus comprises a rail having a plurality of pairs of vertical slots longitudinally spaced apart. A sled slides along this rail and has cross members to which are pivotably attached ends of hydraulic cylinders, the other ends of the hydraulic cylinders being pivotably attached to cross heads which also slide along the rail.

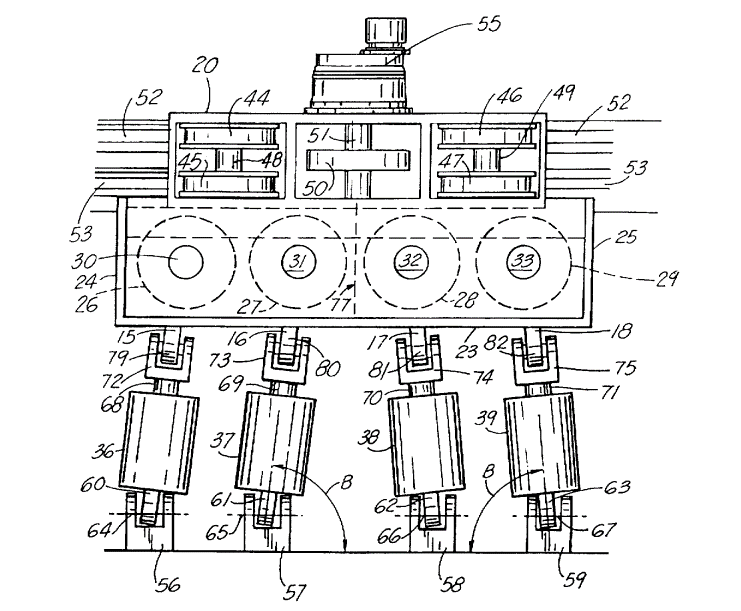

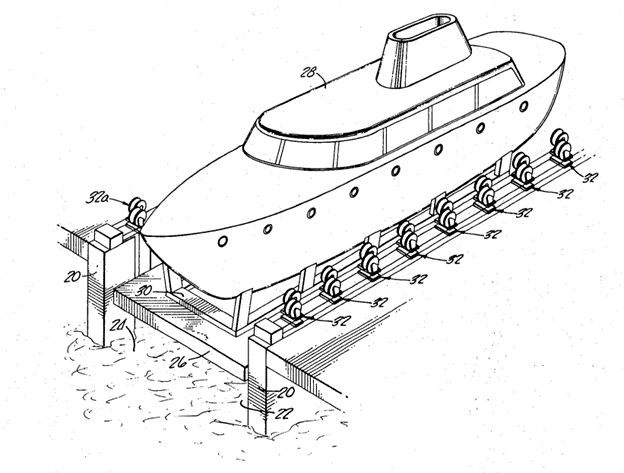

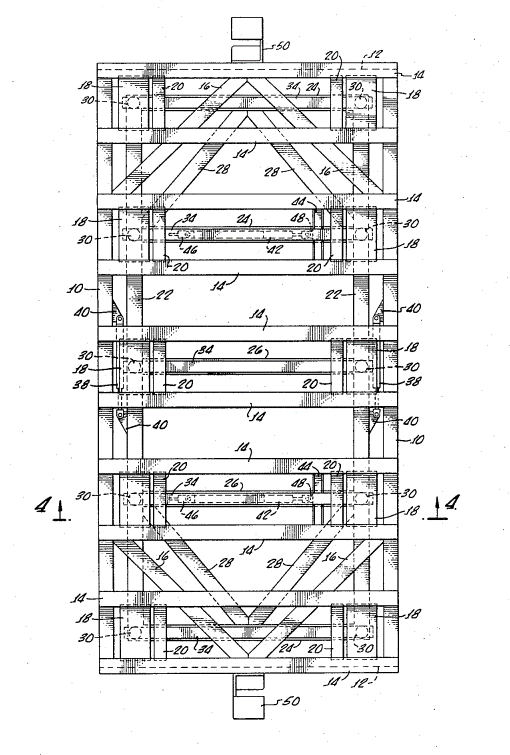

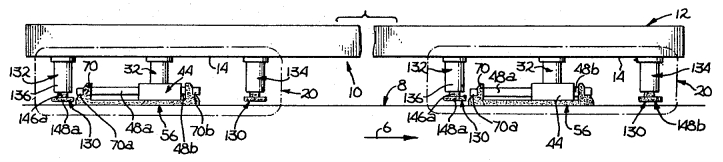

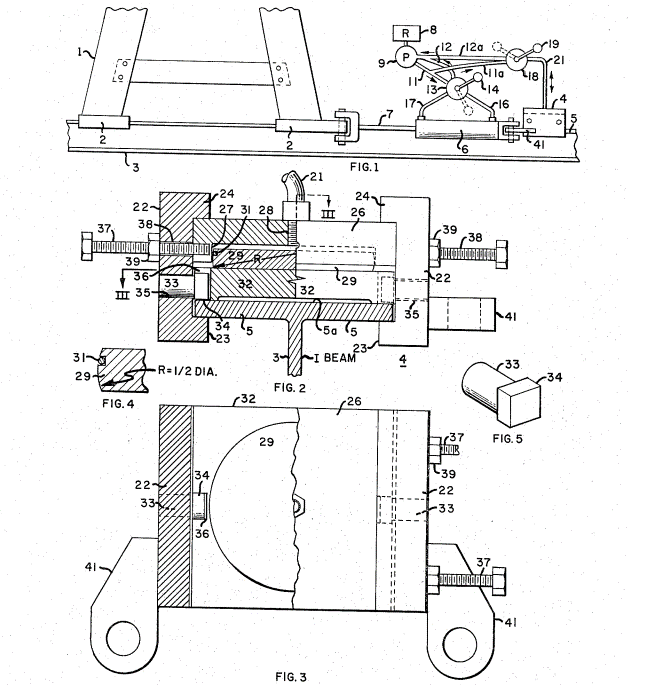

A ship lifting apparatus, or drydock, is formed by a pair of parallel, spaced apart piers, which define a slip in which is located a platform onto which a ship can be floated. The platform is raised or lowered by a plurality of chain jacks mounted in aligned rows on each of the piers.

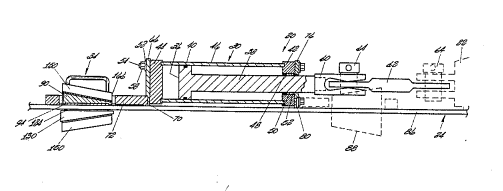

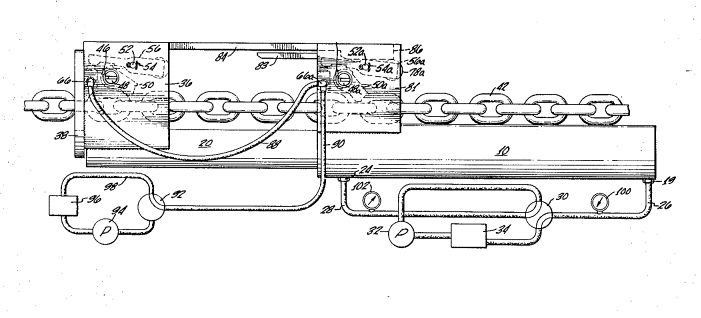

A chain jack is operated by alternately transferring the chain load from a cylinder or base latch mechanism to a ram head latch mechanism and moving the base and the ram head away from and toward each other by alternate extension and retraction of the ram to cause relative movement between the chain and the base.

A single jack ram is straddled by two chains resulting in low cost and a balanced load. Ram head latches and cylinder assembly latches are formed as double pins hydraulically operated and which are oriented at right angles to each other to engage consecutive links of the chain when the ram is completely retracted.

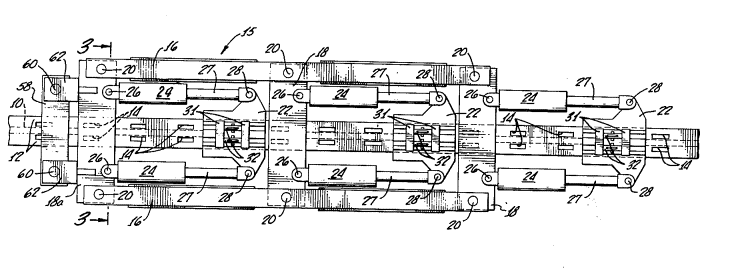

A transporter for heavy loads has an upper pallet with peripheral supporting rails, and a sub-structure inside and spaced apart from the peripheral rails of the upper pallet. Vertical jacks between the substructure and the upper pallet raise or lower these sequentially, and means such as hydraulic cylinders are arranged to provide relative longitudinal or lateral movement between the upper pallet and the sub-structure when one of these is raised from the ground.

Piston Gripper Jacks are used where size and weight restrictions dictate a more compact design, or for very large loads. The Piston Gripper uses an array of separate, short-stroke, hydraulic pistons to clamp the jacking (skid) beam flanges. These grippers develop maximum clamping force with minimum size. Piston Gripper Jacks are smooth-acting, rugged and dependable for years of maintenance-free operation.

Hose Gripper Jacks used a bladder that, when pressurized, force steel clamps against the upper and lower surfaces of the edges of the skid beam flange, locking the gripper into place on the beam. The jacking cylinder was then pressurized to push or pull the load. Hose Gripper Jacks were particularly suitable where exceptionally wide jacking beams are involved.