We help clients design fit-for-purpose facilities across a broad spectrum of marine industries: counseling shipyards and ports, supporting Defence’s mission readiness, and empowering diverse energy industries across offshore wind, oil, and gas.

We deliver guidance built for real-world demands.

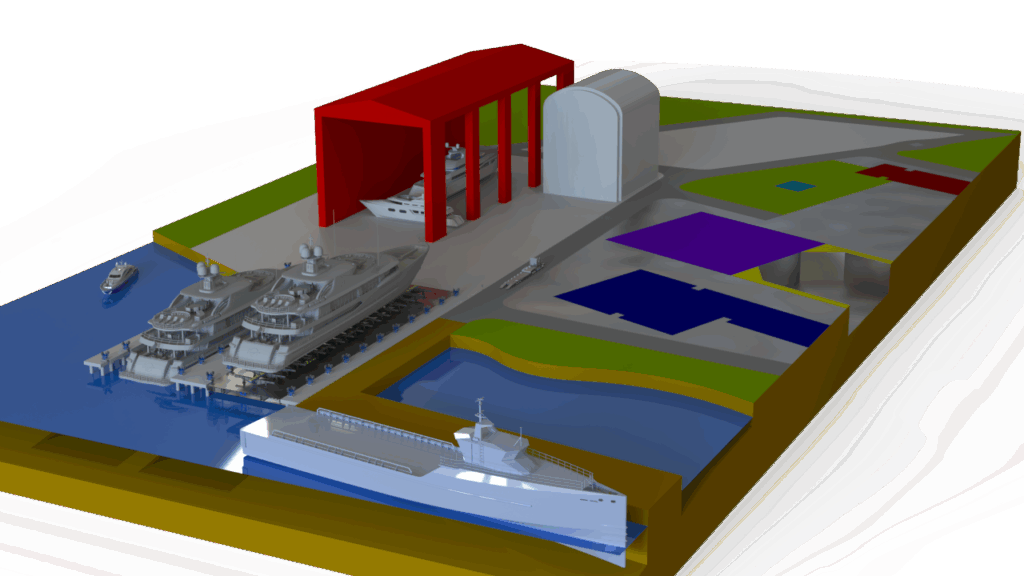

Whether you’re building a new shipyard, expanding an existing facility, or optimizing layout and flow, we help teams work better from the ground up. Our experts bring decades of experience in shipyard design, operational strategy, and maritime engineering to create facilities that perform under pressure.

End-to-End Shipyard Facility Planning Services

Our Advisory Team specializes in shipyard layout planning / conceptual facility planning, infrastructure design (including civil construction means and methods), schematic level engineering design, selection of ship handling technologies and long-term facility development strategies.

Key Services Offered:

Shipyard Master Planning

From greenfield development to brownfield transformation, we design shipyards with future capacity, modularity, and efficiency in mind. Our facility planning incorporates bathymetry, geology, geometry, target vessel market analysis, operational goals, and engineering / procurement / construction (EPC) planning.

We provide conceptual facility modeling including 2D plans, cross-sections, 3D modeling, and site renderings. The model integrates site geometry, channel bathymetry, foundation system(s), ship handling system(s), and facility structure plan. The cross-section modeling is particularly useful for calculating dredge volumes and soil retention requirements. Inclusion of the foundation system(s) allows for creation of 2D plans and material quantity take offs for use in preparing budgets and schedule for one or more conceptual plans and foundation systems.

Workflow Optimization & Layout Engineering

We use your operational objectives to properly map the flow of your facility, eliminating bottlenecks across shiplifts, drydocks, transfer systems, workshops, storage areas, and transport routes.

Infrastructure Assessment & Upgrades

We survey the condition of current infrastructure and use vessel traffic data and future vessel maintenance timelines in your region to recommend targeted upgrades recommend targeted upgrades – from lifting systems to quay-side services – to meet your technical and commercial goals. Dive into the details on our Predictive Analytics here.

Dockmaster and Operator Training

With our partner Von Schmidt Maritime, we deliver tailored training programs for dockmasters and equipment operators to ensure safe, efficient, and compliant day-to-day operations.

Graving Dock Gate Design

Instead of traditional floating gates, we have helped clients implement an innovative design paradigm – the Lift-Out Gate Structure (LOGS) – to revitalize drydock operations. LOGS replaces floating gates with fixed, crane-lifted structures that simplify operations and reduce costs.

Technical Support, Maintenance, and Inspections

Our team provides ongoing technical support, routine maintenance planning, and inspections to keep critical systems running reliably.

Certification Support (Lloyd’s Register, FCR, MIL-STD 1625D, EU Directives)

We help shipyards navigate complex certification processes, including Lloyd’s Register, Facility Certification Reports (FCRs), EU Directives, and the MIL-STD 1625D Standard Practice Safety Certification Program for Drydocking Facilities and Shipbuilding Ways documentation for U.S. Navy compliance.

Compliance with military, commercial, and government requirements

We ensure your facility meets applicable standards across naval and commercial operations including safety, structural integrity, and process documentation. Our team will support compliance with local, regional, and national requirements such as EU directives, environmental regulations, among others.

Design and engineering of new shiplift and transfer systems

From concept through commissioning and beyond, we design custom OmniLift™ shiplift and transfer solutions to match your vessel types, site constraints, and lifting requirements.

Design and supply of Ship Support Systems

We design and manufacture three types of ship support systems: trestles, cradles, and carriages. We can also advise on the best method for uniquely shaped vessels or those with interesting density distributions that may need a custom blocking solution.

Upgrades and modernizations of existing wire rope shiplifts and drydocks

We retrofit and modernize aging wire rope shiplifts, drydocks, and related infrastructure to increase capacity, improve safety, and extend service life.

Frequently Asked Questions (FAQs)

Thinking about long term infrastructure needs should include more than the installation phase of wind farms. Starting in the 5th year of a field’s life, an estimated 5% of turbines will return to port for maintenance. Investing in permanent infrastructure instead of barges means ports will always be ready to support the industry as its needs change. Relying on renting equipment such as ringer cranes opens ports up to risks such as unpredictable availability and pricing. Alternatively, an OmniCraneTM can recover a day rate from multiple industries and avoid both issues surrounding rentals. Additionally, this income will remain in the region and support local jobs instead of sending rental money to international conglomerates.

The Bardex OmniLift™ Launch and Recovery System can readily move equipment back on shore for platform life extension and/or recycling.

Bardex in partnership with Von Schmidt Maritime is well-positioned to help you address this challenge!

Our Advisory Team is made up of Engineers specializing in various areas of shiplift systems and drydocking.