Precision Engineering for Nuclear and Seismic Shiplift Applications

Mission-critical lifting systems for the world’s most demanding environments.

Bardex designs and delivers advanced heavy-lift solutions for naval facilities, nuclear infrastructure, and tectonically active regions where precision, reliability, and safety are non-negotiable. With decades of experience in shiplift technology, we specialize in engineering that meets the highest global standards for earthquake resilience and nuclear-grade reliability.

Trusted for Nuclear and Seismic Critical Operations

From the UK’s Devonport Dockyard to nuclear power facilities in the U.S., Bardex systems are purpose-designed for sensitive, high-stakes applications. Our engineered solutions integrate advanced control systems, laser-guided precision, and proprietary gripper jack skidding technologies to move and position massive structures with unerring accuracy, even in hazardous or high-interference environments.

Case Study: Devonport Royal Dockyard, UK

For Babcock’s submarine refueling facilities, Bardex engineered Transportation & Alignment (T&A) systems to move Reactor Access Houses (RAHs) over nuclear submarines. With 1mm accuracy over 90m of travel and a 30-year design lifespan, these systems demonstrate our expertise in nuclear-safe handling and precision alignment.

Case Study: Oconee Nuclear Station, USA

At Duke Power’s Oconee facility in South Carolina, Bardex designed a 350-ton capacity crane and trolley system for reactor maintenance. The design was tailored to meet the exacting safety and containment standards of nuclear industry operations, showcasing Bardex’s expertise in addressing complex technical requirements.

CASE STUDY: Delivering Critical Earthquake Resistance Designed for -39°C

The Dual Seismic Restraint and Skidding System features a combination of vertical and horizontal restraints paired with Gripper Jacks and Gripper Jack Locking Kits to ensure secure and reliable skidding operations. These elements are also designed to react to forces exceeding 1500 tonnes on the structure simultaneously in all 3 directions – keeping the rig restrained during an earthquake or seismic event.

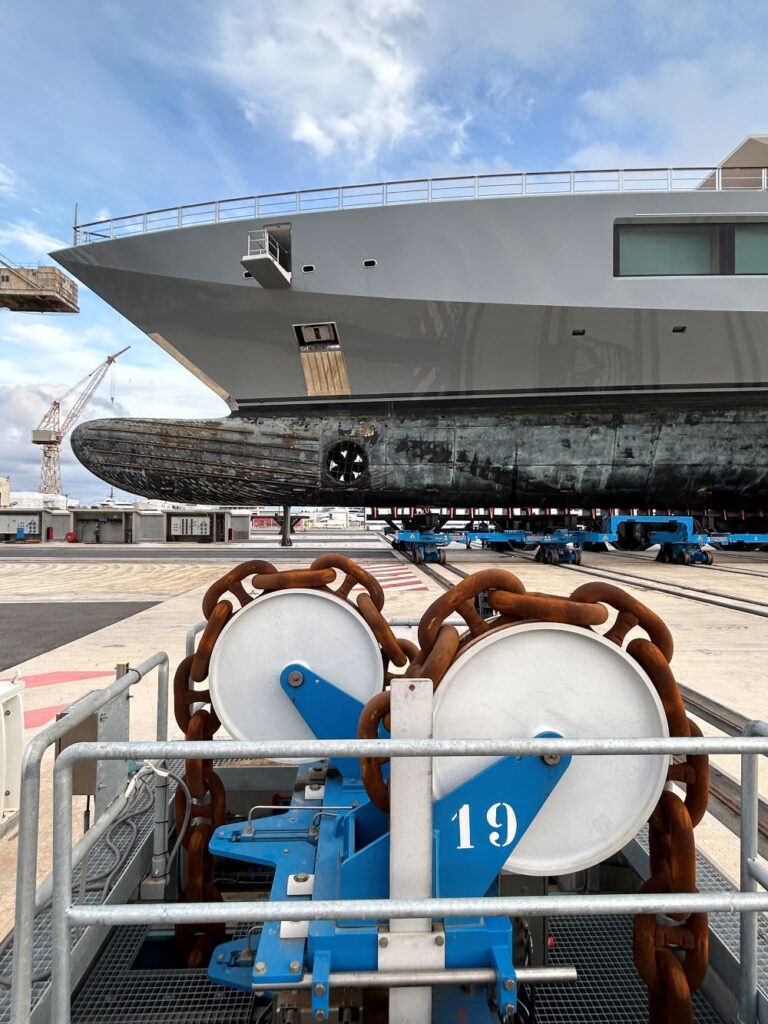

Why Choose a Shiplift Over a Traditional Drydock?

Shiplifts provide unmatched seismological stability. Unlike fixed drydocks, Bardex’s chain-suspended platforms isolate during geological events, swaying independently to absorb shock and prevent structural damage. This design ensures safety for both vessels and personnel, with minimal risk of collision or failure.

Designed for Compliance, Engineered for Confidence

Bardex integrates critical system protections across all designs:

- Seismic Isolation – Chain jack platforms behave as isolated masses, ideal for seismic zones.

- EMC/ESD Resistance – Immune to electromagnetic and static discharge disruptions.

- Magnetic Field Tolerance – Operates reliably in strong magnetic environments.

- Hazardous-Area Standards – Meets or exceeds IEC specifications for nuclear and offshore environments.

Global Expertise. Zero Compromises.

Only three shiplifts worldwide are qualified for nuclear submarines. None are Bardex systems, yet our proven technology and rigorous adherence to nuclear standards position us as a global contender. Our work in offshore oil and gas, where safety standards are unforgiving, further validates our engineering reliability.

No Bardex shiplift system has ever experienced a significant failure or reportable incident.

Read more about our Precision Engineering for Nuclear and Seismic Stability in Heavy-Lift Applications.

Talk to an Engineer

We don’t pitch, we solve. Whether you’re upgrading infrastructure, planning a new facility, or evaluating earthquake readiness, our engineers are ready to collaborate.

Let’s raise the bar together. Schedule a consultation.

Frequently Asked Questions

Bardex systems are designed to meet the rigorous safety, control, and environmental standards required for nuclear facilities. We integrate precision alignment technologies, redundant safety protocols, and compliance with hazardous-area and IEC standards to ensure reliable, long-term operation in mission-critical environments.

Our shiplifts are inherently seismic-resilient due to their chain-suspended platform design. This allows them to move freely during geophysical events, acting as isolated masses and minimizing force transmission to structures or vessels, unlike traditional fixed drydocks.

Yes. Bardex specializes in custom-engineered systems, and much of our work is for military shipyards, submarine facilities, and defense contractors. We have extensive experience designing for restricted-access sites and can integrate secure controls per customer specifications.

Our systems are engineered for longevity. For example, the Devonport Royal Dockyard installations were designed with a 30-year operational lifespan and a structural design life of 50 years. Bardex equipment is built for minimal maintenance and enduring performance under heavy loads and hazardous conditions.

An OmniLift is a shiplift designed with linear chain jacks. As “linear” implies, and unlike a wire rope drum with fleet angles, the chain is always lifted, pulled, or tensioned in a straight line. This efficiency over winch systems means an OmniLift is suitable for lifting everything from frigates to nuclear submarines to entire offshore wind turbine assemblies. Provided sufficient water depth, we’ve yet to encounter a case load that is too large.

The Bardex OmniLift is the only shiplift that has never experienced a significant failure or reportable incident. While other shiplift providers focus on modular shiplift systems, Bardex offers integrated solutions tailored to unique, often complex, site environments while simultaneously delivering a more cost-effective solution over the life of the system. We excel in state-of-the-art control systems, seismic design, and extreme-lift precision. Our solutions are capable of much greater lifting capacities due to the inherently better scaling of chain jacks compared with wire rope winches. And the ocean will thank you for going with chain – no grease enters the water with a Bardex OmniLift.

Read more about the differences between chain jack and wire rope shiplifts.

Absolutely. We routinely design to IEC standards for hazardous areas, as required by nuclear and offshore oil and gas projects. Our systems include protections against electromagnetic interference (EMC), electrostatic discharge (ESD), low-frequency transients, and magnetic field susceptibility.

Shiplifts operate using a synchronized system of winches or chain jacks to lift a vessel vertically out of the water. Once elevated, transfer systems may move the vessel horizontally into shore-side bays or into bays directly behind the shiplift.

Watch our OmniLift shiplift in action.

Drydocks are basin-style enclosures that are flooded to receive a ship and then drained. Shiplifts, by contrast, use a mechanical platform that lifts the vessel directly out of the water. Shiplifts typically require less space, can be automated, and are more seismically resilient. Shiplifts are also safer as work is done either on land or fully out of the water compared to a drydock which may catastrophically flood.