Can’t decide between an OmniLift®, wire rope shiplift, or floating drydock? Skip the trade-offs and get the best of each with the world’s only OmniDock™

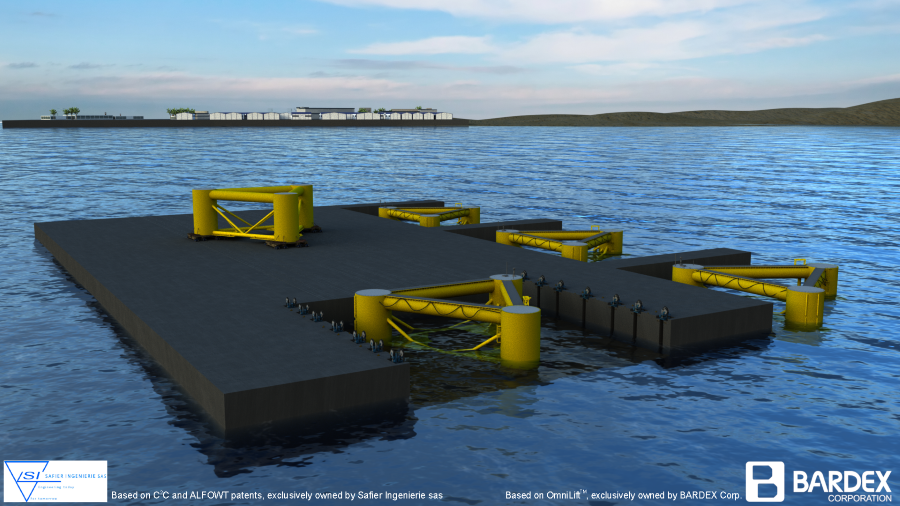

Bardex’s Floating OmniDock™ revolutionizes ocean launching and recovery capabilities. From traditional commercial and military vessels to offshore wind turbines to the uncrewed vessels of the future, the Floating OmniDock™ is infrastructure on the move. Choose from concrete, steel, or a hybrid approach depending on your operational goals and available resources.

Concrete

Supported by the Safier Ingenierie sas ALFOWT modular floating hub and C2C construction method, choosing a single-material concrete OmniDock offers a turn-key solution while avoiding the shipping costs associated with large steel structures.

Steel

Do you have steel fabrication resources available on-site? This build-to-print option for the supporting structure of the OmniDock can greatly reduce your CAPEX.

Hybrid Concrete-Steel

Each project has different resources available and different challenges to address. Choosing a steel topped, concrete base structure for the OmniDock can offer a longer design life with less maintenance cost compared to a pure steel design while still offering the benefits of building, launching and connecting modular concrete caissons found in a uniform concrete design.

Choose an Asset Able to See the World, No Matter How Remote

Improve operational readiness by taking vessel-sustainment or wind-turbine resources to where they’re needed – not just to where the infrastructure was built. Move from island to island, shipyard to shipyard, or port to port with the aid of tugboats.

Optimize by Using All Available Yard Space

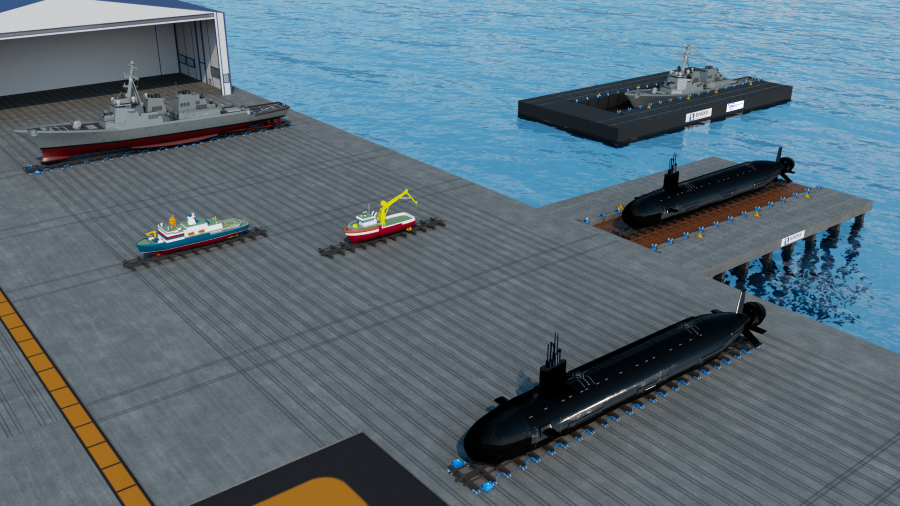

How do you move a vessel from an OmniDock to land? With a transfer system of course!

Flexibility Empowers Your Mission

Boost your ROI with flexible infrastructure that increases vessel lift availability and operational efficiency.

- Gain independence from the tides with the ability to elevate the platform to match the quayside. And because no ballasting is required, there’s no risk of introducing potentially harmful invasive species.

- Whereas a floating drydock accommodates servicing only one vessel at a time, the OmniDock™ can move as many vessels onto land as the yard has space for.

- OmniDock’s mobility maximizes drydock and O&M operations for all seasons: Tow it to a warmer southern region during icy winter months, then return north to support the artic market’s demand.

- Vessel operators can deploy or remove vessels from the water as needed for the season.

Precision Engineering for Nuclear and Seismic Shiplift Applications

Discover how our Precision Engineering capabilities support mission-critical environments, including advanced nuclear work for Babcock’s submarine refueling infrastructure.

Uplifting Local Communities & Removing Barriers

We believe it’s important to support the communities and workforce in the regions where our equipment is installed and relied on for mission-critical use.

- We establish partnerships to support users locally with maintenance and spare parts.

- Ports and local tradespeople have opportunities to train on our systems during commissioning.

- Using locally produced concrete increases the local content of the project.

- Unlike fixed vertical shiplift systems sometimes commonly referred to as a Syncrolift®*, the Bardex® Floating OmniDock™ is a transferrable asset, which simplifies financing.

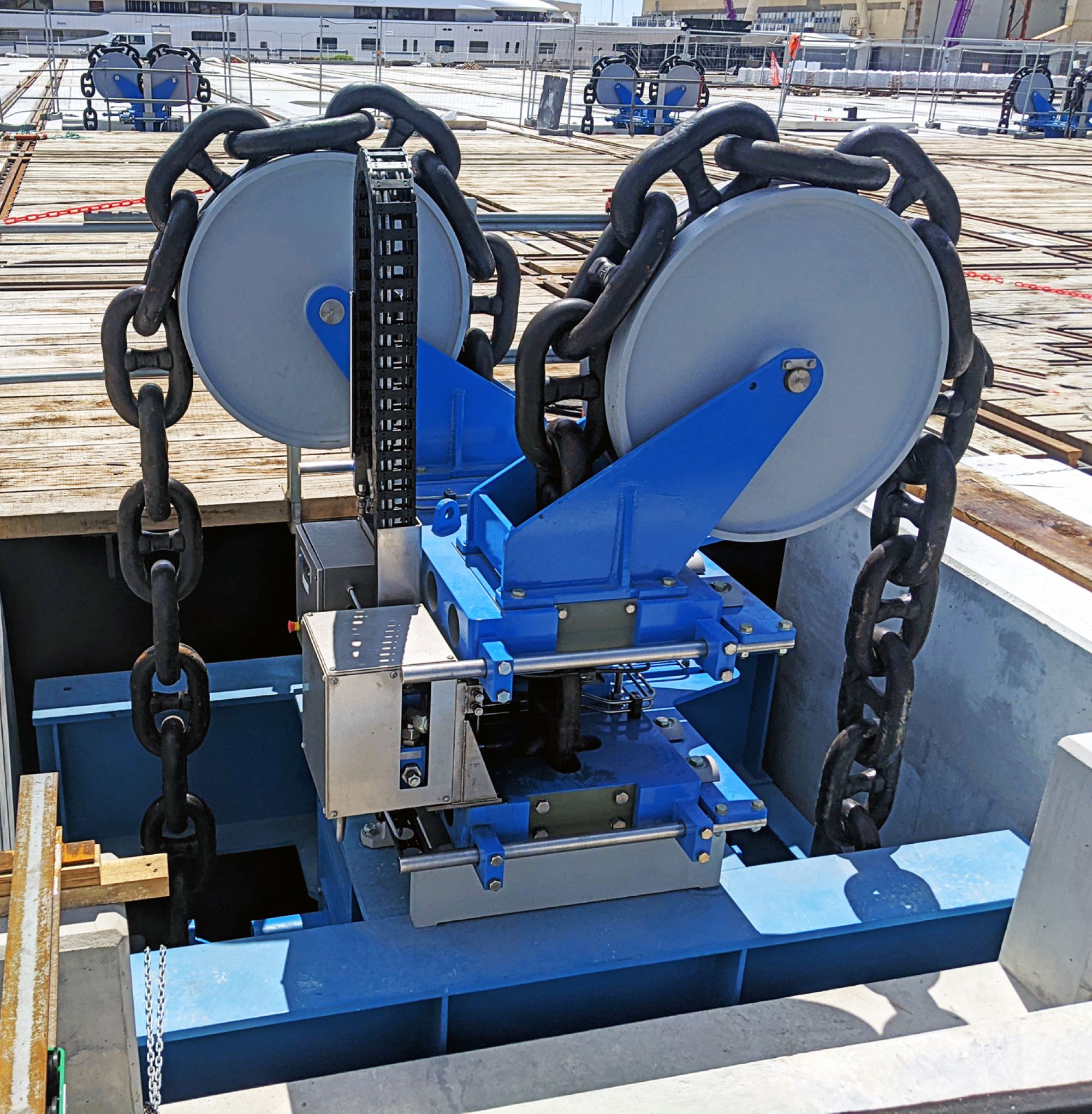

Meet the Linear Chain Jack: Superior to a Wire Rope Winch in 3 Key Ways

- Unlike a wire rope drum with fleet angles, the chain is always lifted, pulled, or tensioned in a straight line. There is no induced link bending stress or interlink wear from bending it around a chainwheel under load.

- The Bardex Linear Chain Jack has a significantly reduced footprint compared with windlasses, winches, and other devices.

- No grease is submerged into the water as part of a maintenance routine. Save money and prevent lubricants from entering the marine environment – for the life of the system.

*Syncrolift® is a registered trademark of Syncrolift AS.