When a shipyard invests in a shiplift, the real question isn’t how to lift a ship — it’s how to keep that lift safe, level, and reliable under real-world conditions. Around the world, three technologies dominate: synchronous-motor shiplift systems, variable frequency drive (VFD) shiplift systems, and OmniLift® chain jack shiplift systems. Each works in a different way: Only OmniLift chain jack systems deliver clear advantages across safety, reliability, and lifecycle cost.

This article breaks down how these drive and control systems work in shiplifts, what their limitations are, and why OmniLift chain jack motion control outperforms wire rope systems as a true drydock alternative. For shipyard modernization projects, understanding these motion control shiplift technologies is critical.

Three Ways Shiplifts Are Powered and Controlled

1. Synchronous-Motor Wire Rope Shiplift Systems

- How they work: Motors are synchronized to grid frequency, ensuring each runs at the same speed.

- The problem: Equal motor speed doesn’t mean equal platform level. Wire ropes stretch more under heavier loads, so the platform drifts out of level as it moves. Current inrush issues, current lag challenges, and higher energy requirements are encountered with this outdated method.

- Consequences: Small misalignments snowball as the platform moves, making tilt worse the farther it travels. Tilt grows with travel, forcing operators to pause or intervene to bring the platform back into tolerance. This costs time and adds risk.

- Bottom line: Motor efficiency gains are irrelevant if platform-level control is lost under real-world loads.

Additional details: Synchronous motors were first applied to shiplifts in the 1950s, when operators often accepted ‘good enough’ alignment instead of demanding today’s higher precision. The term “synchronous” refers only to the motor shaft speed locking to grid frequency — not to the ropes or platform. Because wire rope stretches under load in proportion to the load it carries, each motor may be turning perfectly in step, yet the platform becomes uneven. Imagine four people carrying a beam: Even if they walk in perfect step, the beam tilts if one person is carrying more weight. The same happens here, magnified by hundreds of tons of ship weight. The farther the travel, the more pronounced the tilt, until re-leveling becomes mandatory. This design limitation is inherent and cannot be engineered out without abandoning rope altogether.

Additionally, when synchronous motors are all started at once, there is a huge current inrush, which can trip the main power supply circuit protector and adversely impact other operators on the grid connection, as well as lead to other problems.

Synchronous-motor-driven platforms also go out of level at every start and stop because of the current lag between the motor control center (MCC) located in a central control room and the motors located at each lift station. The motors closest to the MCC start first; those farthest from the MCC lag behind. Operators report having to “reverse” the starting sequence to maintain a level platform when starting and stopping the system.

Synchronous motors also use a lot more energy than VFD-controlled motors and, for this reason, are no longer used in other commercial and industrial applications. The lack of demand over time has constricted the supply chain, making synchronous motors expensive to buy, maintain, and replace.

While synchronous-motor systems were the first generation of wire rope shiplifts, VFD shiplift systems were introduced as the “modernized” alternative.

2. VFD Wire Rope Shiplift Systems

- How they work: Variable frequency drives adjust motor speed and torque with greater precision, offering improved synchronization. Ramping up and down allows VFD systems to avoid the current inrush issues found with the synchronous motor systems.

- The problem: You’re still fighting rope stretch along with major side effects: electrical harmonics that disrupt power quality, excess heat that demands big cooling systems, and a forest of drive cabinets and firmware to maintain.

- Consequences: Complexity adds failure modes. Even with better speed control, rope elasticity means differential loads still cause drift.

- Bottom line: VFD motors are a patch, not a solution. Systems still require frequent re-leveling and higher life-cycle maintenance.

Additional details: VFD-based shiplift systems were introduced as a modern refinement, promising precise speed control and energy efficiency. In theory, feedback loops allow each motor to adapt to minor differences, but in practice, rope stretch overwhelms these corrections. Rope under higher tension stretches more, so even perfect motor control cannot prevent uneven platform tilt. Beyond rope physics, VFD systems introduce their own burdens: electrical harmonics that disrupt power quality, heat loads that demand big cooling systems, and the challenge of synchronizing dozens of drives and firmware revisions over decades of operation.

When one drive trips offline, others may react unpredictably, leading to pauses or emergency stops. While VFD shiplift systems look like a technical advancement, their complexity increases life-cycle cost and reduces reliability because every additional drive and cabinet is another potential point of drift or downtime.

Furthermore, both synchronous-motor and VFD wire rope shiplift systems suffer from the same core weakness — rope stretch. OmniLift chain jack shiplift systems, in contrast, are built on an entirely different principle, making them inherently level-resetting and simpler.

3. Motion Control OmniLift Chain Jack Shiplift Systems

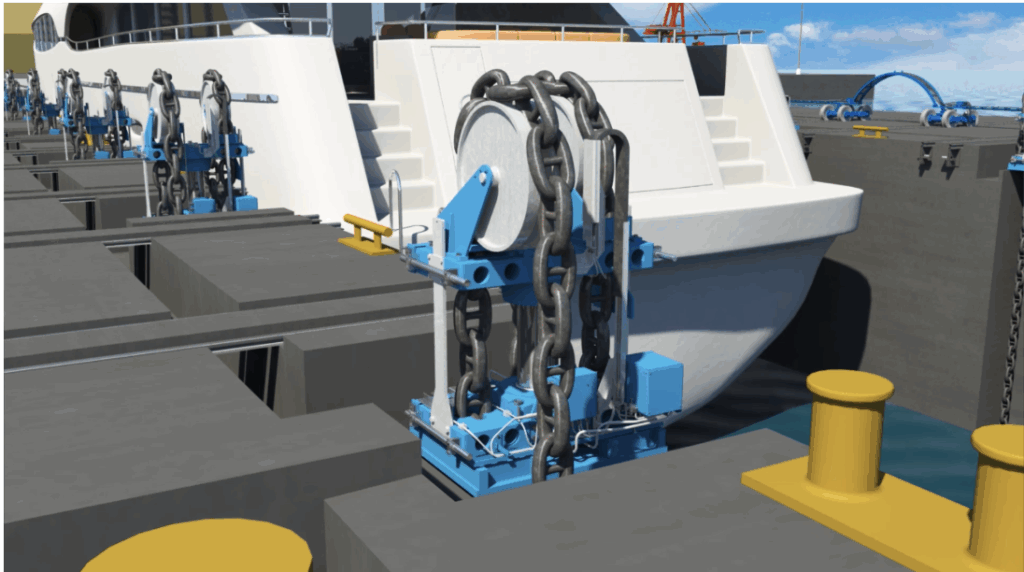

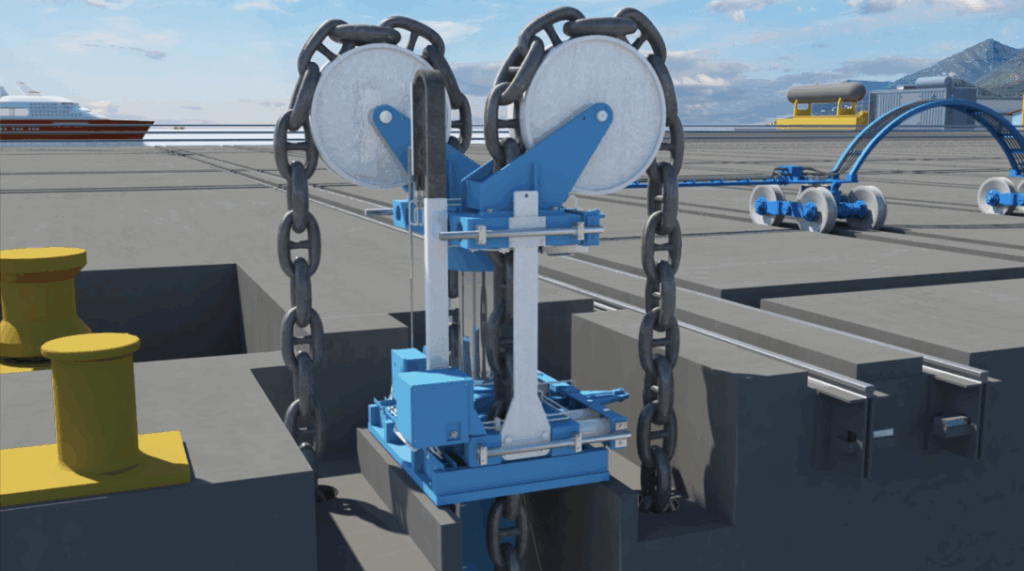

- How they work: Hydraulic chain jacks lift two links at a time, with a motion controller comparing every jack in milliseconds.

See a direct comparison between the OmniLift and a Wire Rope Shiplift.

Get a closer look at the Bardex chain jack in action

- The advantage: Wire rope systems drift because ropes stretch under uneven load. OmniLift resets alignment every stroke, eliminating cumulative error. Fixed stoppers also lock the load safely between strokes, providing inherent fail-safe redundancy.

- Consequences: Unlike VFD rope systems, OmniLift provides precise motion control without harmonics, sidesteps the heavy cooling loads of VFD electronics, and does not rely on a maze of cabinets and firmware.

- Bottom line: OmniLift eliminates rope stretch as a factor and delivers motion control that stays accurate under real loads — without the overhead of complex electronics. Compared with rope-based shiplifts, it is engineered for superior uptime, safety, and long-term simplicity.

Additional details: OmniLift chain jack technology directly addresses the weaknesses of wire rope systems by design. The jack grips two links of chain, pulls them upward, and resets for the next stroke. (It’s like a GPS constantly correcting your position: You’re always on the right path, and small deviations never build up.) Between strokes, fixed chain stoppers physically lock the load, ensuring security even if a hydraulic or electronic component is offline. Unlike VFD rope systems, OmniLift generates no harmonic distortion, doesn’t create excess heat surrounding electronic circuitry that demands big cooling systems, and avoids a maze of drive cabinets and firmware updates. Heat is inevitable when moving large loads, but the heat generated by a chain jack system is dispelled through a simple water-cooling tower or an air/oil heat exchanger, depending on the location and ambient conditions of the site.

Maintenance is predictable: Hydraulic service intervals are straightforward, with far less exposure to the frequent upgrades and obsolescence issues seen in VFD systems. With fewer failure points and built-in safety every stroke, OmniLift delivers a motion-control solution designed not just for today’s shipyard but for the next 50 years of operations.

The Value Case

- Safety: A level platform means lower risk of vessel damage and personnel hazards.

- Uptime: Less re-leveling and debugging means more ships serviced, faster.

- Life-cycle Cost: Predictable maintenance beats the mounting long-term costs that drag down rope-based systems.

- Future-Proofing: Modern yards need systems that last 50 years. OmniLift is built for that horizon.

For shipyard modernization projects, these factors go beyond technical differences — they directly shape safety, uptime, and profitability for decades. In each case, the difference comes down to how the system controls motion under load. Only OmniLift provides hardware-level resets that guarantee accuracy.

The Bottom Line

Shiplifts aren’t just about raw lifting power — they’re about staying level, safe, and reliable under the uneven realities of real ships. Wire rope shiplift systems, whether driven by synchronous motors or VFDs, ultimately drift because rope stretches. OmniLift chain jack shiplifts reset alignment every stroke, eliminating cumulative error by design. For shipyards planning long-term, the difference is decisive. That makes OmniLift the clear drydock alternative, built on true motion control.

Frequently Asked Questions (FAQs)

Common buyer questions include:

Wire rope shiplift systems, whether synchronous motor or VFD-driven, struggle to stay level because ropes stretch more under heavy sections of a vessel, causing tilt that grows with travel. OmniLift chain jack shiplifts avoid this by hard-resetting alignment every two-link stroke, so drift cannot accumulate.

In wire rope VFD shiplift systems, continuous drive coordination is required; otherwise, if a motor or drive trips, drift or imbalance can result. OmniLift chain jack shiplifts are fail-safe. Fixed stoppers lock the load between every stroke, so even in the event of a hydraulic or sensor issue, the platform remains secure.

Wire rope VFD shiplift systems involve large banks of drive cabinets, cooling systems, and firmware management, each adding potential points of failure. OmniLift chain-jack shiplifts use straightforward, predictable hydraulic service and a simpler control architecture with fewer electronics, reducing maintenance complexity.

Motor efficiency differences are marginal compared to the operational impact of downtime. A slightly more efficient motor does not compensate for repeated re-leveling, drive trips, or rope replacements. OmniLift chain jack shiplifts prioritize reliability by design, eliminating cumulative error and minimizing downtime.

While wire rope shiplift systems may appear lower-cost at purchase, their long-term expenses — rope replacement, electrical upgrades, harmonic filters, drive failures — add up significantly. OmniLift chain jack shiplifts reduce unplanned downtime and maintenance overhead, offering lower total cost of ownership and a future-proof drydock alternative.

Shipyard infrastructure is a once-in-a-generation investment. The choice of shiplift technology shapes safety, uptime, and profitability for decades. OmniLift chain jack shiplifts eliminate drift by design, keep platforms level under real loads, and simplify long-term maintenance.

Ready to evaluate your options?

Schedule a consultation with our technical experts to review your yard’s needs, explore life-cycle cost comparisons, and see how an OmniLift chain jack shiplift solution can future-proof your operations.