Photo Credit: Oceantic Network

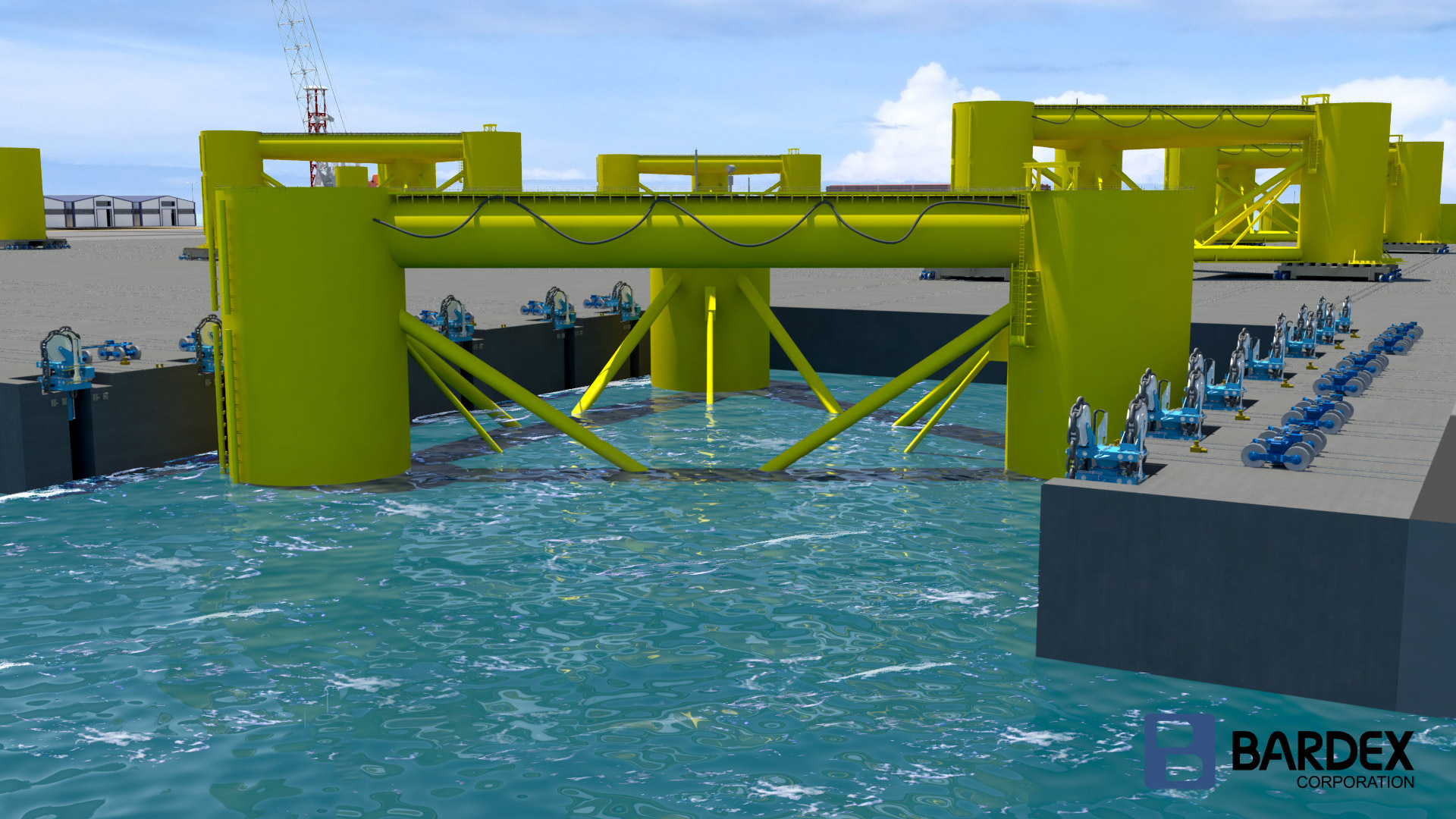

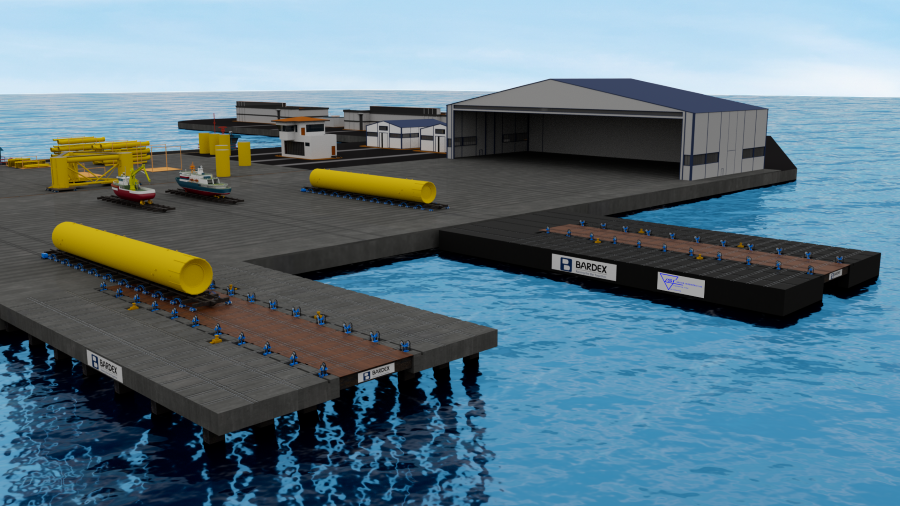

OmniLift®

This award-finalist lifting platform can launch and retrieve floating wind foundations, marine structures, and vessels.

Photo Credit: Oceantic Network

3 Technologies Integrated into 1 Multi-Purpose Device

The OmniLift® integrates three proven engineering technologies: shiplift chain jacks, the long-span steel truss, and lift span bridges. By combining these technologies in a new way, we have innovated a high-capacity, long-span lift platform capable of launching and retrieving floating wind foundations, marine structures, and vessels. Using modern materials and design tools, the design and construction of an OmniLift is well within the capability of any modern economy. The expected service life of the investment is at least 50 years.

The Only Functional and Economical Choice

Unique to the Bardex® system is its ability to directly lower the floater for wet tow and retrieve floaters back to dry land to perform major O&M (operations and maintenance) or to extend the life of the FOSW (floating offshore wind) platforms. No other system can do this. This breakthrough improves the supply chain process and streamlines the assembly process for serial production by providing an integrated extension to the existing quayside and adding an additional assembly area. The assembly of large FOSW platforms, like semi‐submersibles, TLPs (tension leg platforms), etc., can take place on a stable surface, and the assembled systems can be directly lowered for wet tow, reducing the health and safety risks. Compared to floating methods, the OmniLift system is a simpler, safer, and more controlled solution:

Is not subject to as many Health & Safety variables as a semi‐submersible barge, such as wave height and quayside mooring

Does not require ballasting operations to support load-out

Does not require offshore tugs for stability

Is not tide dependent

Read Robert Taylor’s paper, “Improving Multi-Use Port Facilities through Key Design Parameters”, presented at the 35th PIANC World Congress in South Africa.

Read Robert Taylor’s paper, “OmniLift Littoral Heavy Lift System Design”, presented at the 3rd PIANC Asia Pacific Conference in Sydney, Australia.

Socially Responsible

The OmniLift provides a method of retrieving the wind turbines for recycling or reuse.

The OmniLift system can serve as a drydock for decades after the windfarm installation is completed, providing business opportunities to port and ship repair industries and job opportunities to the local workforce.

Reduces emissions from offshore service vessels (OSV) by providing a local maintenance facility.

Platform installation generally optimizes local content and workforce.

By leveraging and integrating the strengths of proven technologies, Bardex has created a revolutionary lifting device that expands heavy-lift capability beyond what, until now, was thought possible.

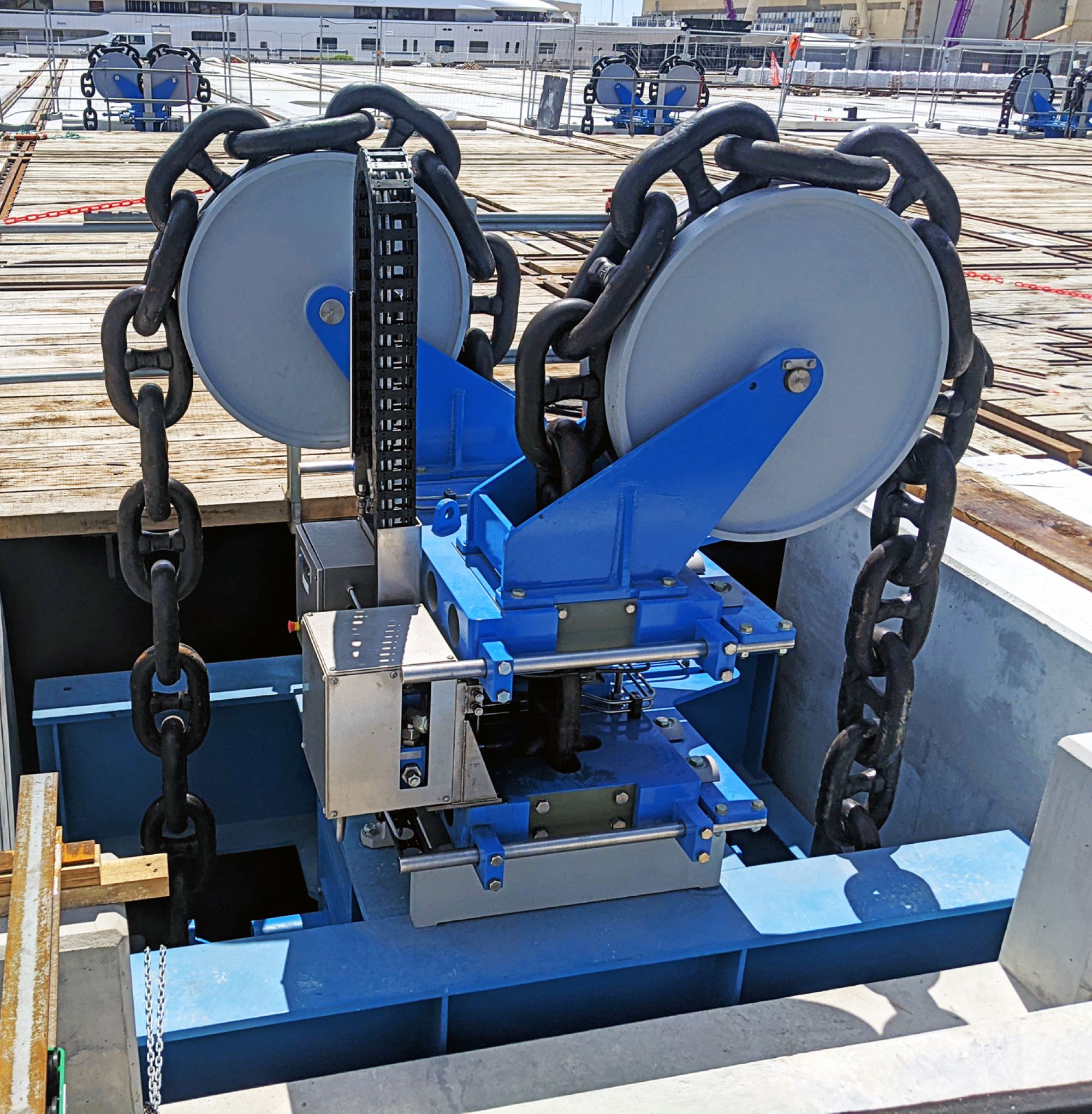

A Chain Jack? What’s that?

The gold standard for shiplift technology

One of Bardex’s most important product innovations and contributions to the heavy load handling industry is the Linear Chain Jack. This piece of equipment represents one of the safest and most efficient ways to lift, tension, or move heavy loads using chain.

Unlike a wire rope drum with fleet angles, and as the word “Linear” in the product’s name implies, the chain is always lifted, pulled, or tensioned in a straight line. There are no induced link bending stresses or interlink wear from bending it around a chainwheel under load.

The Bardex Linear Chain Jack has a significantly reduced footprint compared with windlasses, winches, and other devices.

Bardex has designed the Linear Chain Jack so that the chain is always mechanically held by either the fixed or traveling latches. This makes it impossible for the chain to be released inadvertently due to loss of hydraulic power or operator error.